EvoAPS exists to change that.

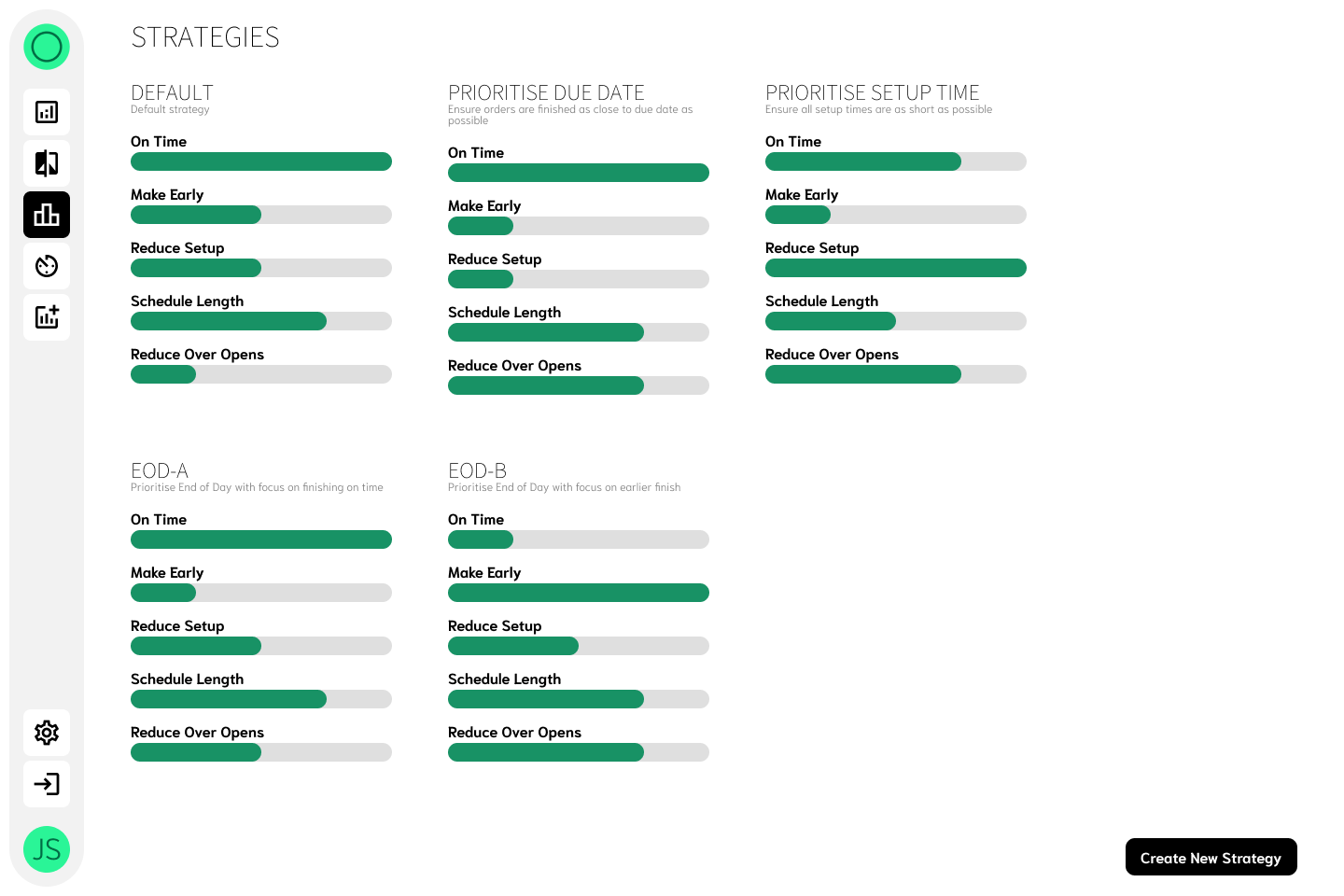

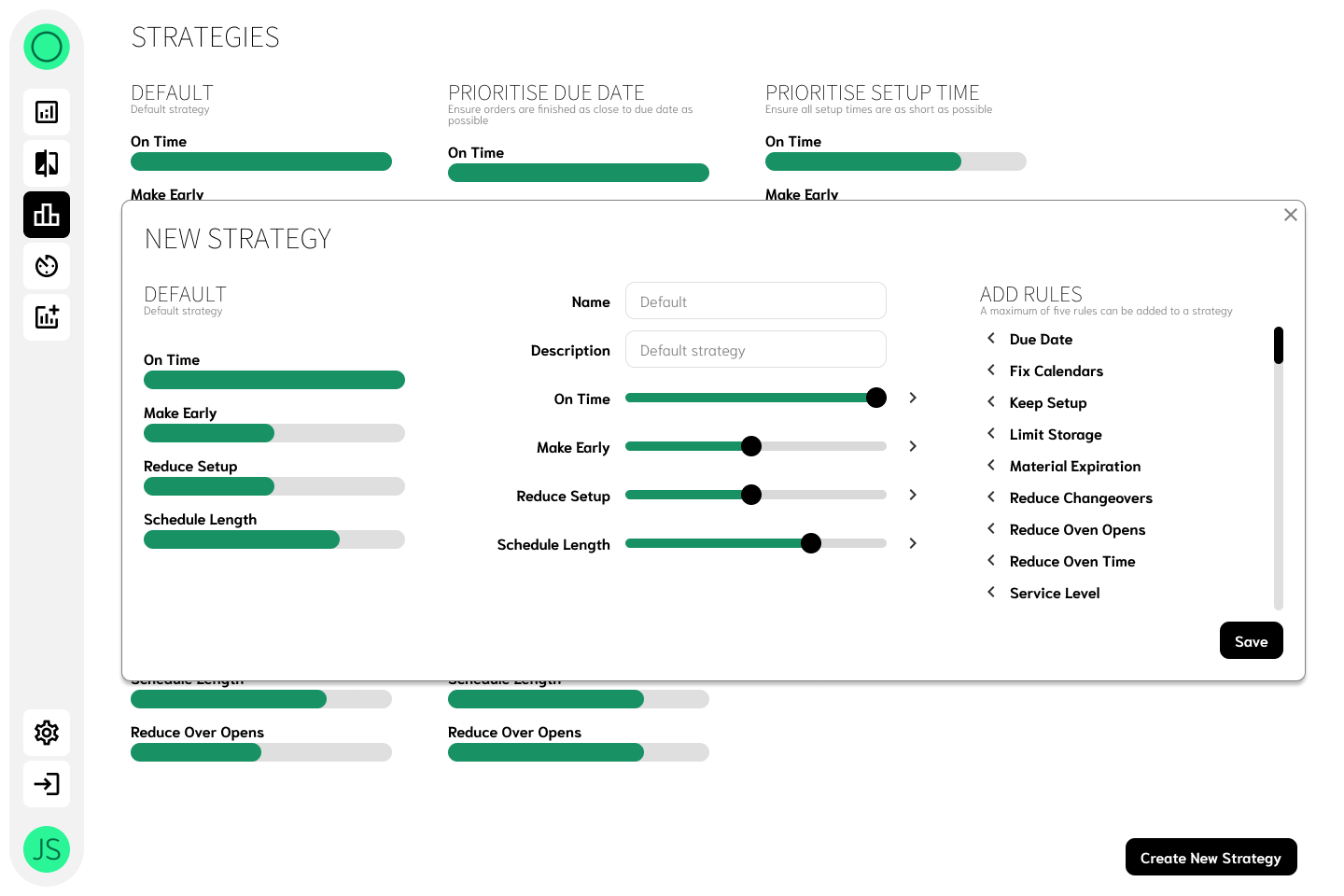

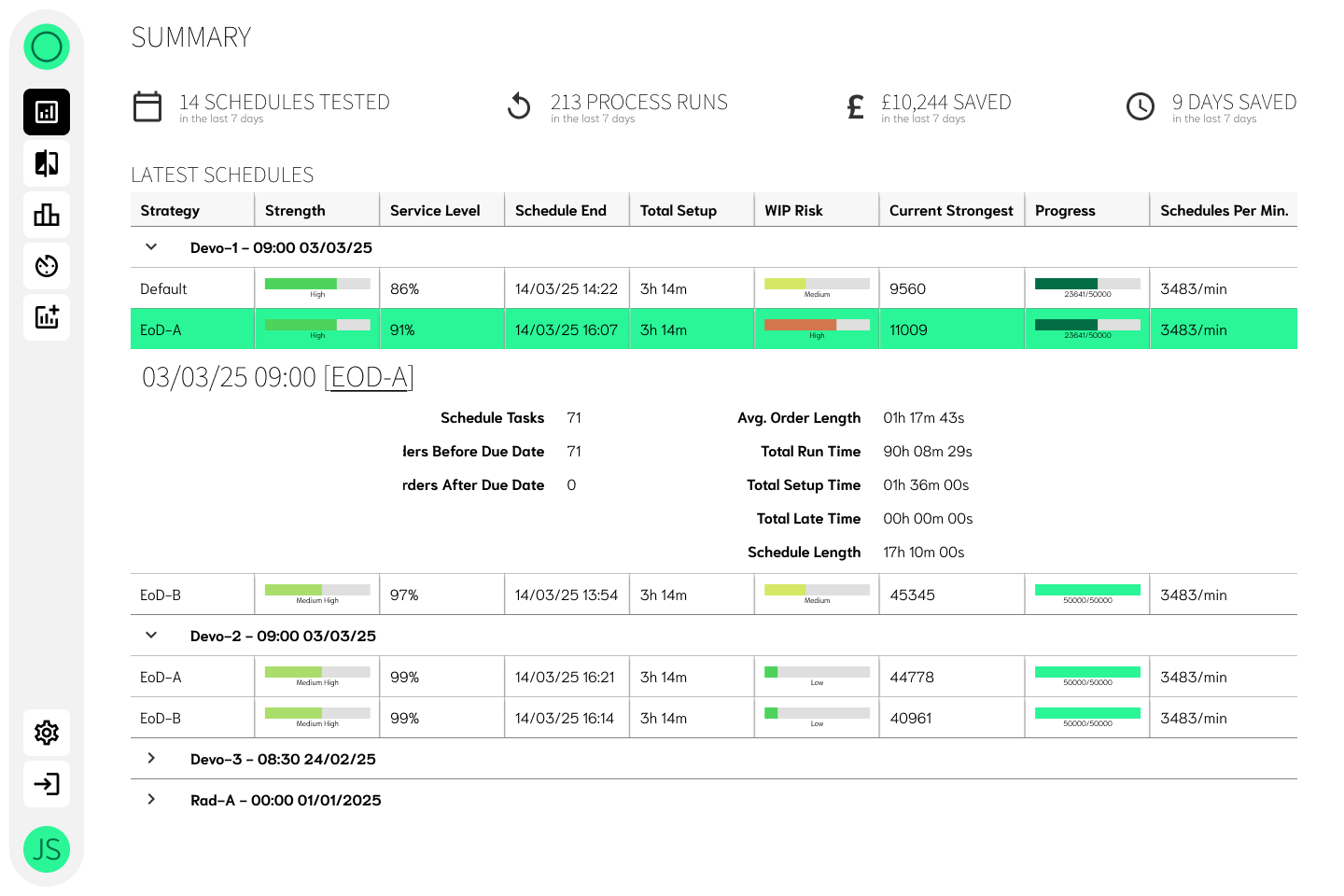

EvoAPS is a strategy-driven scheduling engine designed for complex, real-world manufacturing environments. Instead of producing a single “best” schedule based on fixed rules, EvoAPS explores thousands of valid scheduling options in parallel and evaluates them against what the business actually cares about — service, efficiency, stability, utilisation, or flow.

It turns scheduling from a reactive task into a deliberate decision-making process.

At its core, EvoAPS gives manufacturers the ability to ask better questions:

- What happens if we prioritise customer service over efficiency?

- What trade-offs are we making to reduce changeovers?

- Is there a more stable way to run the same factory?

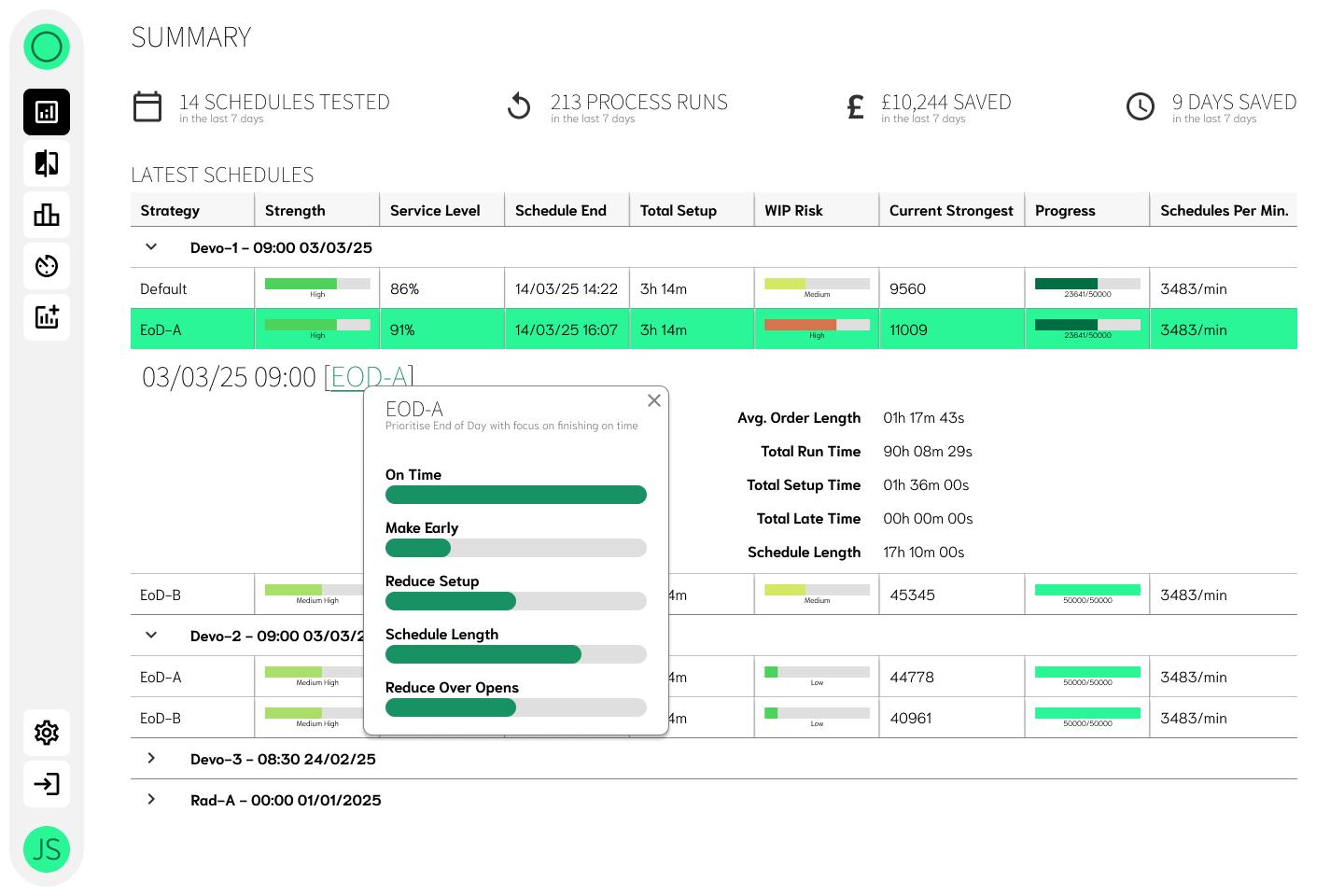

EvoAPS shows the consequences of each choice clearly — so leaders and planners can make informed decisions with confidence.

Just as importantly, EvoAPS is not about replacing people. It is designed to support planners, not remove them. The system does the heavy computational work — exploring possibilities, testing strategies, and comparing outcomes — so experienced people can focus on judgement, problem-solving, and keeping production flowing.

In simple terms, EvoAPS is like a sat-nav for manufacturing operations.

The destination is defined by the business. EvoAPS shows multiple routes. The people remain firmly in control of the wheel.

That’s why EvoAPS exists

To reduce operational stress, remove unnecessary risk, and give manufacturers a smarter, more resilient way to plan and schedule as complexity continues to grow.

The Problem EvoAPS Solves

Manufacturing scheduling rarely fails because people aren’t capable.

It fails because the environment has outgrown the tools used to manage it.

As operations become more complex, traditional scheduling approaches struggle to keep up — leaving planners and leaders constantly reacting instead of making deliberate, confident decisions. EvoAPS is designed to address the root causes of that problem.

1. Conflicting priorities with no clear trade-offs

Most scheduling tools force planners into a single way of working — optimise for due dates, or for efficiency, or for utilisation.

In reality, manufacturing is about trade-offs.

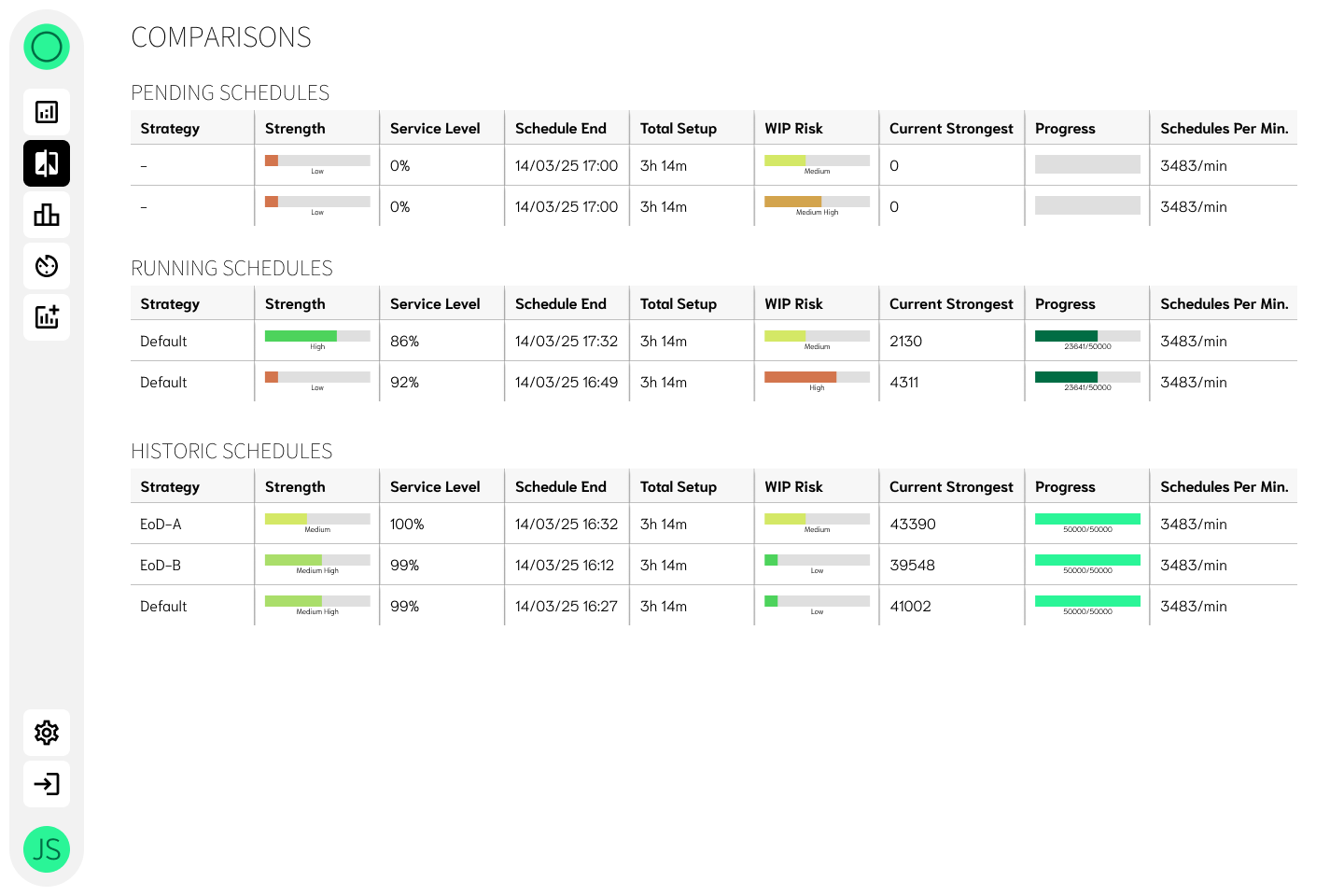

EvoAPS allows multiple strategies to be explored at the same time, showing exactly what happens when priorities change. Instead of guessing, teams can see the consequences of each decision and choose the option that best aligns with current business goals.

2. Over-reliance on individual expertise

In many organisations, planning success depends on a small number of highly experienced individuals. When they are unavailable — or when the business scales — risk increases and performance becomes fragile.

EvoAPS captures planning intent in strategies, not in people’s heads. This reduces dependency on individual knowledge, improves consistency, and builds operational resilience without removing human oversight.

3. Firefighting caused by constant disruption

Late materials. Machine breakdowns. Last-minute demand changes.

Traditional scheduling requires manual rebuilds every time something changes — consuming time and increasing stress.

EvoAPS continuously explores alternatives in the background, making it faster and easier to respond to disruption without starting again from scratch. Fixed planning windows protect near-term execution while still allowing rapid re-optimisation further ahead.

4. Slow, reactive decision-making

When schedules take hours or days to rebuild, decisions are delayed — or made with incomplete information.

EvoAPS dramatically shortens the time it takes to evaluate options, enabling teams to move from reactive problem-solving to proactive control. Leaders can make decisions quickly, knowing the trade-offs have already been assessed.

5. Growing complexity without scalable control

As SKU counts increase, routings multiply, and operations expand, scheduling complexity rises faster than headcount or tools can cope with.

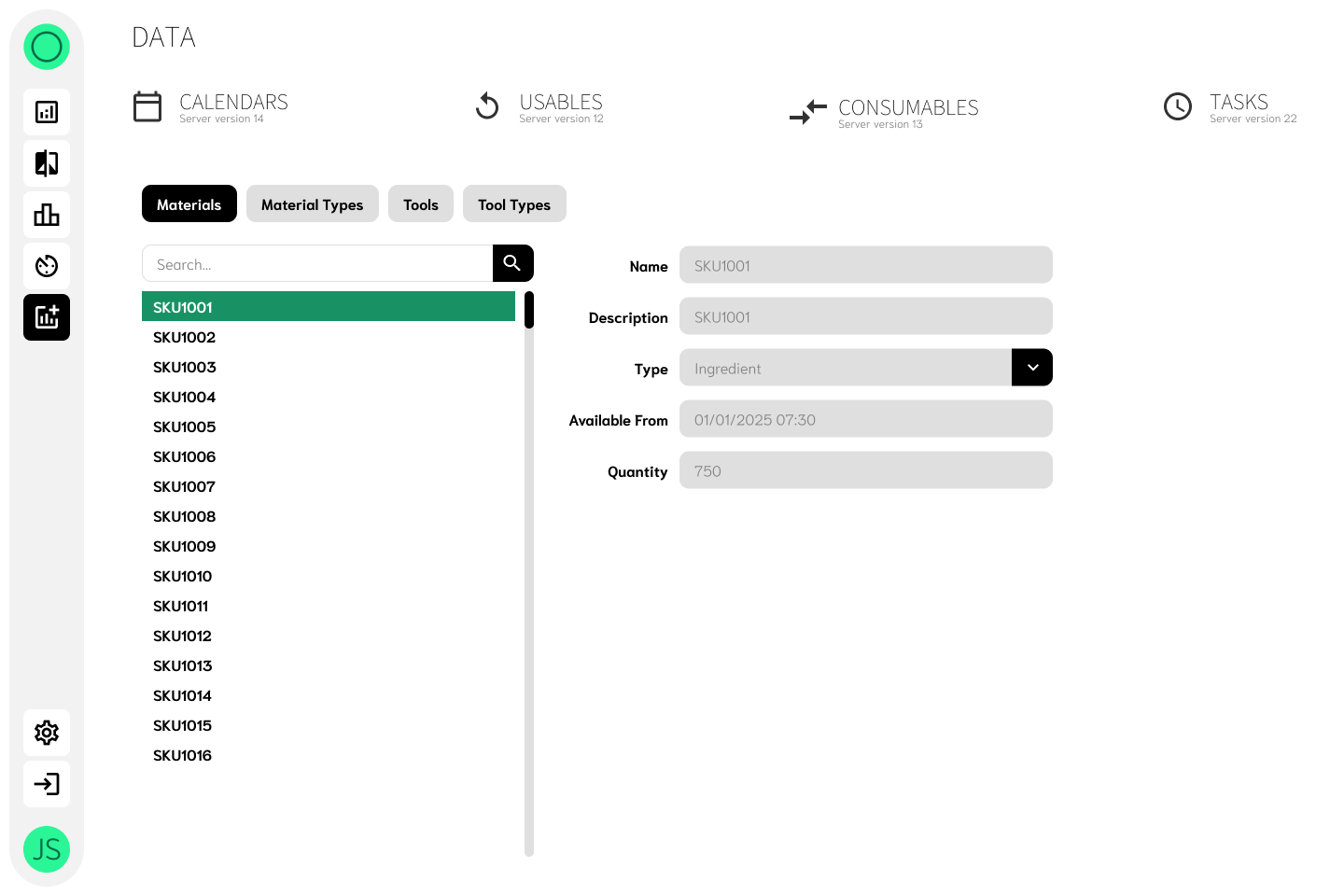

EvoAPS scales with the business. It handles complexity computationally rather than manually, allowing manufacturers to grow without proportionally increasing planning effort or risk.

6. Lack of visibility and confidence in decisions

Without clear insight into why a schedule looks the way it does, confidence suffers — especially when decisions need to be explained to production teams, commercial stakeholders, or the board.

EvoAPS provides transparency by comparing schedules, highlighting improvements, and showing how different strategies impact outcomes. Decisions become easier to explain, defend, and repeat.